Cross-Flow-Filtration

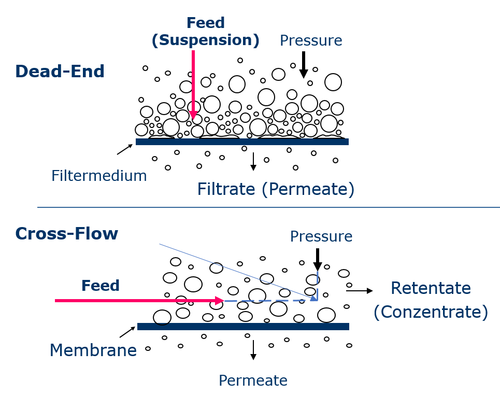

Unlike the cake-forming dead-end filtration, crossflow filtration (also referred to as tangential flow filtration) largely avoids the formation of a filter cake.

In crossflow filtration the fluid to be filtered is pumped in parallel to a filter medium or a membrane and the filtrate (also referred to as permeate) is removed perpendicularly to the flow direction. The shear forces appearing at the filter surface because of the turbulent flux can be varied depending on the volume flow.

Because of the high speed, it is largely avoided that a filter cake (a surface layer) develops out of the solid particles to be separated (fluid components to be separated) on the filter medium and / or membrane. It would increase the filtration resistance and hence the pressure loss across the filter, and this would involve a higher complexity of equipment and energy.

Whilst the solids to be separated are recovered in dead-end filter systems as filter cake, the solids can in crossflow filtration only be concentrated to the extent that the suspension is still pumpable; the filtrate is in both cases free from solids. The part of the liquid flux not passing through the filter medium / membrane is referred to as retentate.

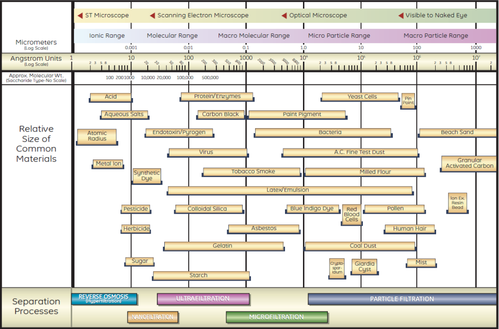

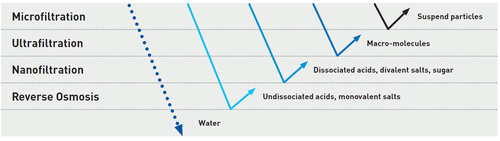

As opposed to the static dead-end filtration techniques, the crossflow filtration can treat liquids with relatively high trub contents by microfiltration and ultrafiltration.

The preferred applications are areas in which a high particle occurrence or large concentration gradients are to be aexpected. As a result of the permanent outflow of the retentate, an equilibrium value arises during further concentration which can be maintained for a long time.

Tubular and hollow fibre membrane modules are particularly suited for this purpose.

In the field of nanofiltration and ultrafiltration spiral wound membrane modules are preferred.

Products for Cross-Flow-Filtration

Schematic Sketch Dead-End- and Cross-Flow-Filtration: