Cross-Flow-Membrane-Modules

We are a provider of technically individual high-quality products into niche markets. We are specialized in the distribution of membranes and the trade with membrane accessories. Our core competences lie in our know-how in the field of membrane technology.

Membrane-Modules

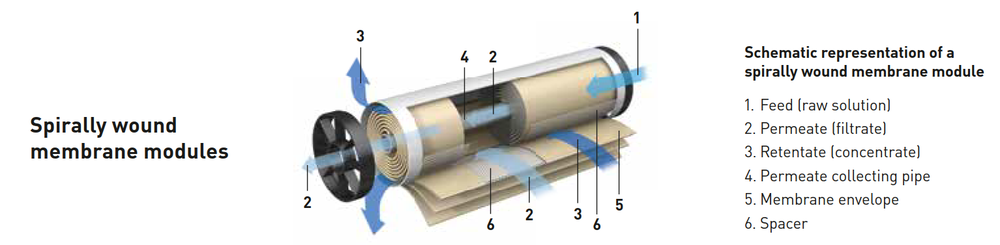

Spiral modules basically belong to the category of thin channel modules, which offer a very large membrane surface in a very compact space. Spiral modules are used in food production, paint separation and waste water technology with a low proportion of suspended particles. In a spiral arrangement, several layers of supporting layer-reinforced flat membranes and spacers are wound around a central permeate tube in a sandwich-like manner. The process fluid enters the module at the front end and then flows into the free spaces formed by the spacers axially through the entire length of the module and leaves the module at the other end. The permeate flows through the membrane, collects in the permeate chamber and then flows spirally to the permeate collecting tube from where it is discharged. Spiral modules are available in various lengths, diameters and flow channel heights. Spiral module systems are very compact and save pump energy.

Tubular membrane filtration modules are modules with open flow channels.

There are different flow channel widths with a diameter of mostly 5.5 to 25 mm. The currently most common type has a membrane tube diameter of 8 or 10 mm. Tubular modules are manufactured as single tubes or in bundled configurations and are installed in housings. The membrane layer of the tube module is applied to a reinforced carrier material. The product to be filtered flows through the pipe module at a flow velocity that is as defined as possible. The permeate (filtrate) flows radially through the membrane and the support tube and reaches a permeate collection chamber from which it is discharged. The great advantage of the tube modules lies in their ability to achieve a high concentration without clogging, even with media with a high solids content. Tubular module systems do not require any costly pre-filtration, as is absolutely necessary for other systems with thinner duct cross-sections. Another main advantage of tubular module products is the possibility of good cleaning of the system.

Due to our new partnership with ORELIS Environnement in the field of ceramic membranes for high-performance applications in Germany our range of possible application-specific solutions is extended by an important building block.

The KLEANSEP™ ceramic membranes and modules show their unique strength, more particularly, in the field of oil/water separation, like the treatment of degreasing baths, the industrial wastewater treatment for use as process water and the recovery of recyclable materials up to the sterile filtration of milk.

You can find an overview of our range of services in our brochure.

Cooperation/Manufacturer

The membranes are manufactured in France by the Alsys company und are very well-known and established under the name of Orelis/KLEANSEP™. Orelis is one of the leading manufacturers of ce-ramic membrane elements and operates all over the world with its prod-ucts. Corresponding experience but also pilot plants and test centres are hence available for support in the application.

Lehmann&Voss&Co. represents these products in Germany and the surrounding regions.

In addition to the well-known ceramic and polymer-based membranes for microfiltration, metallic membranes are also available. These are a metallic sinter which is pressed into a membrane under defined conditions. These membranes are used where, due to the prevailing application conditions, the medium is very abrasive and the previously mentioned membranes no longer offer sufficient service life. These membranes are also successfully used at high temperatures. Various exclusion limits are available.

Application area of membrane technology

In the production of chemical and pharmaceutical products, separation processes play the most important role alongside the actual implementation.

Membrane technology ensures safe and economical compliance with the separation requirements of the pharmaceutical industry. From sterilization and depyrogenation of process water for fermentation, separation of enzymes and isolation of active ingredients from fermentation broths to final purification of the applicable end products.

The food industry has always appreciated the advantages of membrane technology. This technology is used with great success for the clarification of wine, vinegar and fruit juices. In addition, the dealcoholisation of beers is now carried out by dialysis using membranes. Gelatine, soft cheese, quark and whey proteins are now produced using membrane technologies. Efficient production processes for high-quality food require high-performance filters with a high quality standard and optimal economic orientation. Membrane technology has contributed significantly to this high level of technology and will always support this industry with innovative products.

Car bodies, automotive parts, household appliances or office furniture are nowadays primed by an electrophoretic coating method, the so-called e-coating. Of central importance for this technology are the paint bath care as well as the rinse water treatment by ultrafiltration. However, before these parts can be fed to the paint shop, they must be cleaned. Thus it belongs today to the state of the art in the bath care of rinsing baths to use membrane technology.

Click here for further information!

Based on the unique stability of the membrane materials with highest selectivity and functional design of the membrane elements, membrane products can be separated under extreme process conditions. In addition to the chemical industry, which processes a large number of the most aggressive process fluids, the metalworking industry is increasingly resorting to membrane processes.

Not only rinsing water, but also contaminated acids and alkalis from chemical syntheses, galvanic processes or stainless steel pickling can be clarified reliably and economically and often recycled without problems.

Water management in the paper and textile manufacturing industry has long been the job of process engineers. The membrane technology enables intelligent products for the reduction of the enormous water demand. Starting with process water purification, through numerous recyclables and water recirculation systems, e.g. press water recirculation and coating colour recycling, to waste water purification. In all process steps, membrane products for the efficient performance of these purification stages can be found today in modern factories as state-of-the-art technology.

Our lives are increasingly being accompanied by modern electronic data processing. Electronic devices surround us in almost all situations. In order to further increase the performance of these products, it is of utmost importance to install powerful processors and circuits in the smallest possible space. Membrane products are available to this industry, which are used reliably for water treatment and waste water purification for the production of printed circuit boards and chips. Only the purest water without conductivity can be used in production and this is only possible with the aid of membranes.

Membrane separation processes have proven themselves in environmental protection and are becoming increasingly popular due to their versatile and reliable applicability. Membrane technology has proven itself both in municipal and industrial wastewater treatment processes. Membrane processes are only in rare cases optimally applicable as the only process step in the solution of practical separation tasks. Rather, intelligently selected process combinations often lead to economically and technically meaningful results.

The largest market for membrane applications is seen in the international markets for water supply (excursus: chapter 8) and waste water treatment.

The reasons for this lie in the scarcity of natural drinking water resources, the increase in the world’s population and the associated increase in the use of surface water (lakes, rivers, oceans), the composition of which places high demands on purification processes due to industrial pollution. But process water in drinking water quality is also an important resource for the manufacturing industry. No clean water, no clean or pure products.

Presentations

- Membrane Theory

- Decentralized waste water treatment by means of biology and membrane support

- Economic Service Life Extension by optimal Bath Care

- Treatment of abrasive waste water from the glass and ceramics industries using PP modules

- Cleaning in place (CIP)

- Maintenance of a degreasing bath by membrane filtration