Precoat filtration with filter aids

This is one of the most common filtration techniques for separating suspensions. Precoat filter systems have proved their worth particularly when an extremely blank filtrate needs to be obtained. A distinction is made between pressure and vacuum filters with a wide range of different designs in which the filter elements are covered with fabrics, mainly produced from synthetic fibres or metal. Other porous materials can act as filter elements. The filter aid is deposited on these elements as the actual filtering layer.

Precoat filtration is beneficial if the substances causing the turbidity in the liquid to be clarified are small and compressible. If filtered conventionally, these particles would form an impervious film on the filter element and block it within a short time or pass through the filter element and remain in the filtrate or end product as turbidity.

In order to avoid this and to design the filtration process cost-effectively, filter aids such as diatomaceous earth, perlite and cellulose are employed, which can be added at the same time as the liquid to be clarified. They take on the actual filtration task and thus form a growing but permeable filter cake enclosing the suspended particles and thus avoiding the formation of an impermeable film. The filter elements act exclusively as carriers for the deposited filter aid.

Celite diatomaceous earth filter aids

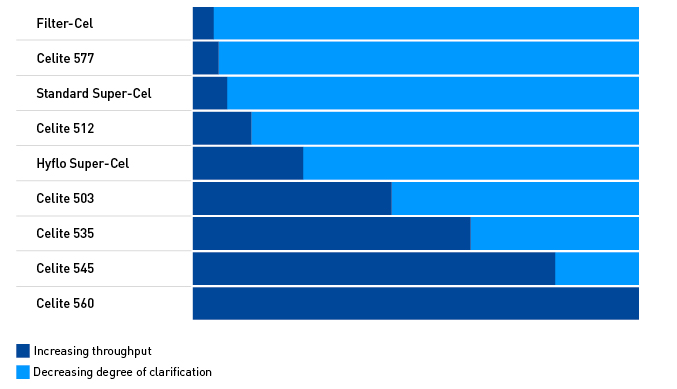

Among the commonly used filter aids, diatomaceous earth is especially versatile and efficient. These fossilized skeletons of diatoms (single-celled algae) also known as kieselguhr offer benefits such as chemical inertness, a large surface area of up to 20 m² per gram and highest possible purity.

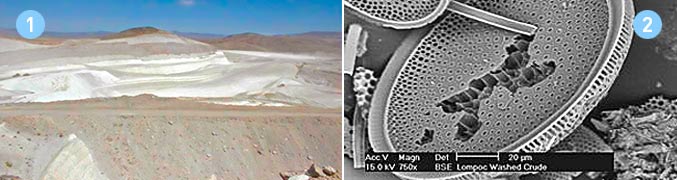

The most important manufacturer of diatomaceous earth filter aids with the largest and purest deposits of diatomaceous earth in the world is the Celite Corp. in Lompoc, California. Other Celite deposits are located in the US state of Washington as well as in France, Spain, Mexico, Chile and China. Celite diatomaceous earth filter aids are prepared from especially high-grade diatomaceous earth deposits.

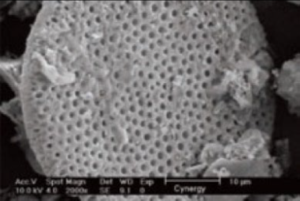

The selection of a suitable Celite filter aid depends on which liquid is to be filtered and what requirements are placed on the result of the filtration process. Diatomaceous earth filter aids permit optimum clarification even for slimy colloidal turbidities smaller than 0.1 µ. In these applications they achieve highest possible throughputs while ensuring maximum purity and chemical inertness. The product to be filtered does not undergo any deterioration in terms of taste, odour or chemical composition, which, especially in the case of beer or fruit juice, is a crucial factor. The constant quality of the Celite filter aids ensures this.

Optimum cost-efficiency with Celite diatomaceous earth

Only if the right filter aid is correctly used it will guarantee all the benefits of this filtration method. Our applications technicians will support you in selecting the products and operating settings that best match the conditions of your plant.

Apart from those listed above, further filter aids are available for special applications such as USP/NF and ultra pure filter aids for the biopharmaceutical and pharmaceutical industry as well as for special applications in the chemical and food industries.

Our experience will also help you to produce better products more cost-effectively.

More than filtration

In addition to the numerous applications available in filtration, diatomaceous earth is also a starting material for other Celite specialities such as: functional fillers, absorptive silicates, substrates for chromatographic work, catalyst carriers.

Sustainability Information

- Our contract supplier Imerys is a signatory of the UN Global Compact and has a Ecovadis certification: Learn more!

- This is how used diatomaceous earth can be recycled: Learn more!

Long-term availability of diatomaceous earth secured

In 2016, global diatomaceous earth production was estimated at just under three million tonnes. In the same year, the world's currently known and so far untouched reserves were estimated at about one billion tons. These reserves alone would cover the current worldwide demand for diatomaceous earth for about 500 years. A resource assessment of the Lompoc mining area in California showed that this deposit alone would cover the current global demand for several hundred years. The supply of diatomaceous earth is thus also secured in the long term.

Recent publication

Diatomaceous Earth - Filter aid for economical beer filtration

Please find the technical paper here (only available in german language)!

Celite Cynergy® 200HS

- Improved utilisation of the solids space

- Improved filter life

- Reduced specific filter aid use

- Fewer filter cycles

- Improved pressure curves

- Reduced amount of filter sludge

- Reduced recycling costs

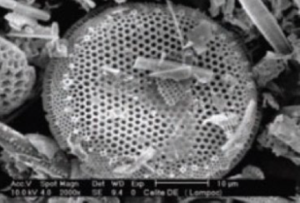

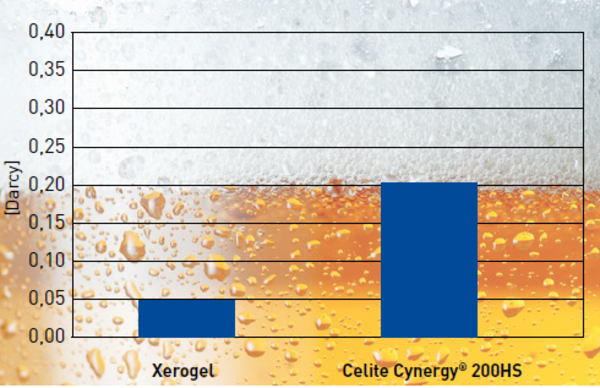

By combining two tasks in one product and a higher permeability (Darcy) compared to usually very fine silica xerogel, Celite Cynergy® 200HS increases the efficiency of your filtration and reduces costs. Following the successful launch of Celite Cynergy® 200 in 2010, which has the same adsorptive properties as a silica hydrogel, we are now pleased to present the new Celite Cynergy® 200HS (HS = High Stability) variant. The adsorptive effect of Celite Cynergy® 200HS is comparable to that of a silica xerogel.

Stabilising and economical

Celite Cynergy® is a beer-stabilising diatomaceous earth which, in addition to the usual filtration properties of a medium-fine diatomaceous earth, has additional protein stabilising properties due to targeted surface modification. Like a silica gel, Celite Cynergy® acts adsorptively to remove selective proteins and thus improves the colloidal stability of the beer. In terms of quantity, Celite Cynergy® replaces the usual amount of silica gel as well as proportionally the normal diatomaceous earth dosage. Celite Cynergy® is added to the beer immediately before the filter via the diatomaceous earth dosage vessel or a separate dosage unit for stabilising agents. A contact time is not required.

Higher permeability

Very fine diatomaceous gel particles block parts of the diatomaceous earth pores during filtration. The blocked diatomaceous earth pores no longer actively participate in the filtration and have a negative effect on the pressure curve. When using Celite Cynergy®, the negative effect of partially blocked diatomaceous earth pores is eliminated.

Application examples from practice

| Diatomaceous earth [g/hl] | Protein stabilisation [g/hl] | |

|---|---|---|

| Diatomaceous earth & Xerogel | 134 | 98 |

| Diatomaceous earth & Celite Cynergy® 200HS | 39 | 96 |

| Reduction diatomaceous earth dosage | - 71 % | |

| Diatomaceous earth & Xerogel | 159 | 76 |

| Diatomaceous earth & Celite Cynergy® 200HS | 88 | 71 |

| Reduction diatomaceous earth dosage | - 45 % | |

| Diatomaceous earth & Xerogel | 69 | 18 |

| Diatomaceous earth & Celite Cynergy® 200HS | 48 | 17 |

| Reduction diatomaceous earth dosage | - 30 % | |

| Diatomaceous earth & Xerogel | 123 | 37 |

| Diatomaceous earth & Celite Cynergy® 200HS | 82 | 39 |

| Reduction diatomaceous earth dosage | - 33 % |

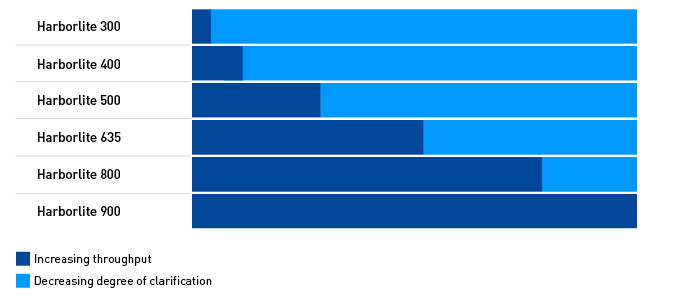

Harborlite perlite filter aids

In contrast to Celite diatomaceous earth filter aids, which consist of almost pure silicic acid, Harborlite perlite filter aids are produced from volcanic obsidian rock by thermal expansion. Chemically, this is aluminium silicate which is almost as inert as silicic acid.

In terms of their structure, Harborlite perlite filter aids correspond to irregular fragments of spheres which do not have the same porosity as the intricate skeletons of the diatoms. Consequently, Harborlite perlite filter aids cannot be expected to produce the same degree of clarification with the same throughput as Celite diatomaceous filter aids. The benefits lie quite clearly in their cost-effectiveness: for instance, Harborlite perlite filter aids are more economical in the clarification of apple juice concentrate and are also free of cristobalite.

In three European plants, Celite Corp produces high-quality perlite grades using state-of-the-art processing methods that usefully supplement the diatomaceous earth range of filter aids.

Harborlite perlite filter aids are a cost-effective alternative

Depending on the application, perlite filter aids can provide a lower cost alternative to filtration with diatomaceous earth. Talk to our experts about your needs and objectives. Together we will find the optimum solution for your application.

Sustainability Information

Our contract supplier Imerys is a signatory of the UN Global Compact and has a Ecovadis certification: Learn more!

LUVOZELL cellulose fibres as filter aids

LUVOZELL is the brand name for the ultra pure cellulose fibres supplied by Lehmann&Voss&Co. in various lengths. These products are used for forming filter cakes but can also be used as a singular filter aid in precoat filtration.

Cellulose fibres are not economical as a singular filter aid in the brewing industry due to their short service lives. However, in blends with diatomaceous earth and perlite, cellulose fibres can indeed contribute to keeping the filter cake stable on the filter medium.

The use of cristobalite-free cellulose fibres as the sole filter aid can definitely be helpful in the filtration of sugar molasses and cloudy fruit juices. In contrast, perlite-cellulose mixtures have proven to be very effective for fruit juice concentrates.