Dead-End-Filtration

Dead-End-Filtration is considered as the classical form of filtration.

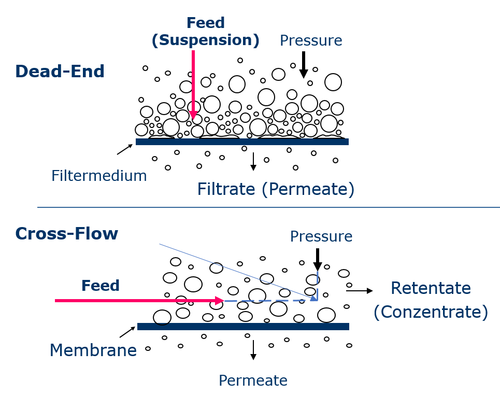

As opposed to Cross-Flow-Filtration (also referred to as tangential flow filtration), a filter cake is formed in Dead-End-Filtration. Dead-End-Filtration is, therefore, part of Surface-Filtration.

Principle of Dead-End-Filtration

In Dead-End-Filtration a particle-containing fluid (liquid, gas) is pumped against the filter medium. Pressure is as low as possible to minimise the compaction of the retained substances. As a result of the permanent outflow of the filtrate, a filter cake accumulates from the solid particles to be separated on the filter medium. This can also have a positive effect on the filtrate quality because the filter cake formation can result in an additional depth filter effect, depending on the pore structure and permeability of the filter cake.

A specialty of Dead-End-Filtration is precoat filtration:

In this case, the filter cake formation deliberately caused on a filter medium by depositing filter aids is also used for the separation of very fine particles in the controlled pore structure of the filter cake. The actual filter medium only acts as a carrier for the filtering filter cake.

The filter cake increases the filtration resistance and hence the pressure loss above the filter medium. For this reason, the filter cake must be removed, depending on the solid concentration in the inflow, at regular intervals by backwashing and possibly by chemical purification so that the filter element can be regenerated or the filter element is replaced by a new one and rejected after an irreversible exhaustion.

The preferred fields of application are areas in which a low particle occurrence or lower concentration gradients have to be expected as well as in classical discontinuous batch operation.

As a result of the permanent flowing against the filter medium, the filtrate flux decreases constantly and there is a “sawtooth pattern” in the filtrate stream as a result of the backwashing and / or replacement of the filter elements. The characteristics of dead-end filtration include, therefore, recurring production interruptions and product losses by backwashing or replacement of the filter elements.

The higher energy efficiency of Dead-End-Filtration versus Cross-Flow-Filtration is an advantage because in Cross-Flow-Filtration a large part of the energy invested in the delivery of the feed is lost through the retentate. When it is possible to do without Cross-Flow-Filtration, Dead-End-Filtration is used. Another argument in favour of Dead-End-Filtration is that it has a quite simple structure.

Products for Dead-End-Filtration:

Filteraids for precoat filtration

Schematic sketch of Dead-End-Filtration and Cross-Flow-Filtration: